Case Study: Local Production Opportunities for Assistive Technology

Case Study: Local Production Opportunities for Assistive Technology

Ben Oldfrey

Innovation Action is a collaborative initiative led by UCL Engineering and funded by UK aid which brings together a consortium of partners working on developing innovations aiming to address global challenges. One of the key projects undertaken by the consortium focuses on the development of various mechanisms by which local production ecosystems can facilitate the co-creation of devices with AT users, local makers, and global expertise to improve access to the continued services that people with disabilities need. This is through an interconnected system of design platforms and mapping initiatives that allows for better connections throughout the design and production value chain.

Problem:

Previous work analyzing the challenges of access to AT in the Global South has shown that current models by which AT are delivered to low resource settings are inadequate [179,250]. Global supply chains, while highly efficient, do not allow the provision of devices that fully meet the needs of individuals, particularly those who have confounding disabilities, but also due to the specific environment or culture they live in. They also will never result in self-reliant local business models for the supply of AT, which would facilitate better, and sorely needed, follow-on services.

Parallel to this, during the COVID-19 pandemic it became clear that global supply chains were not capable of achieving equitable access to the supply needs of personal protective equipment (PPE) either as well as other medical supplies, including AT. They also limited sustainable design and manufacturing approaches.

Co-created new system approach:

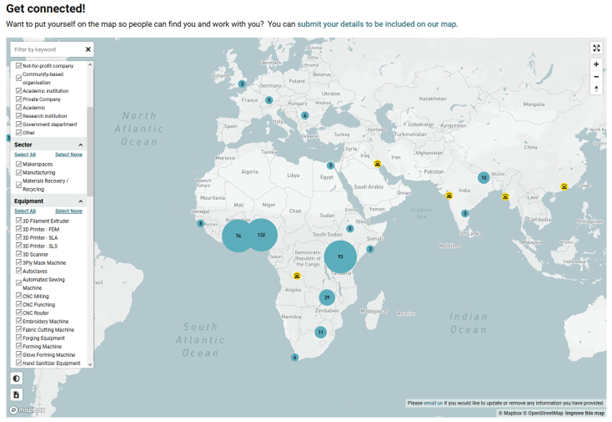

The new approach to AT production we are developing with partners globally using open ways of collaborating at scale. As part of this, the consortium is developing a series of diverse initiatives. First, we are mapping production capacities across different areas of the globe (including maker spaces, manufacturing facilities and production centers) to help designers understand what manufacturing and production capacities are available in their areas ensuring that they can develop products which can be made in their local ecosystems. Secondly we are supporting the development of platforms that enable the connection between end-users who need bespoke devices with manufacturers that can create appropriate designs and make the required products. An example of this is the sharing platform called Makerko in Nepal which helps to address some of the challenges linked to fragile supply chains by leveraging distributed manufacturing and supports direct connections between users and makers to promote the development of technology that truly answers to local demands.

Figure 3.3: Get Connected! Want to put yourself on the map so people can find you and work with you? You can submit your details to be included on our map.

Conclusion: By promoting the creation of better local and global connections between users and innovators and by mapping available resources in local areas Innovation Action helps communities to move towards empowerment and self-reliance in when it comes to the production of AP. This can be boosted by creating peer-peer links between parallel initiatives targeting manufacturing and supply chain strengthening more in general to ensure the creation of sustainable and scalable local AT access models.

Excerpted from Disability Interactions: Creating Inclusive Innovations by Catherine Holloway and Giulia Barbareschi, https://doi.org/10.1007/978-3-031-03759-7, pages 48–50.